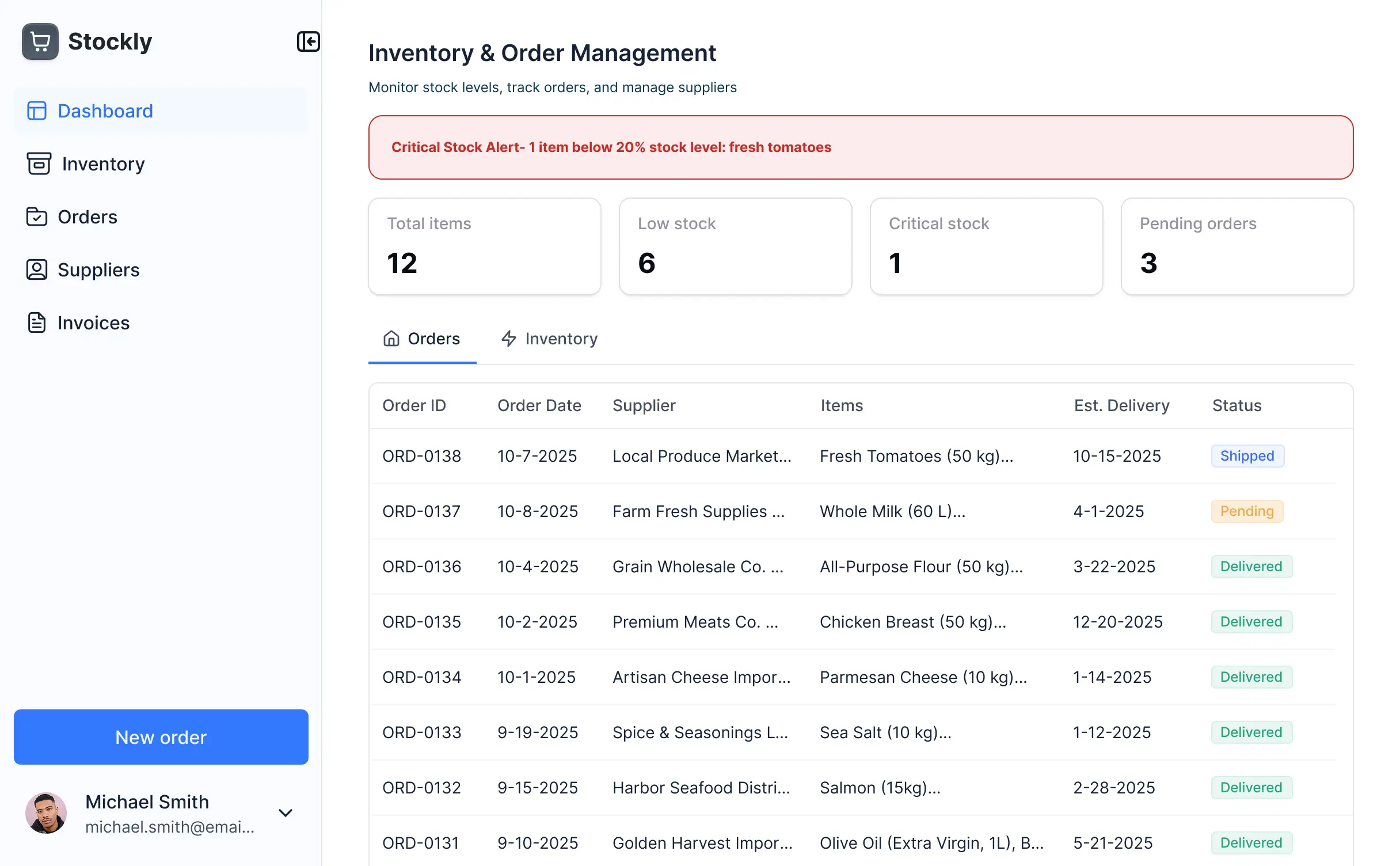

Build food manufacturing inventory management software, no code required

Track ingredients, manage stock, and streamline production with a custom inventory app tailored to your food manufacturing process.

Customize your inventory tool around your processes

Add only the inventory management features and views your team needs. Start simple, then adapt and grow your setup as your workflows change.

Unify your inventory data in real time

Connect spreadsheets, ERPs, and other systems with real-time sync—or manage everything in Softr Databases. Create a single source of truth for your inventory.

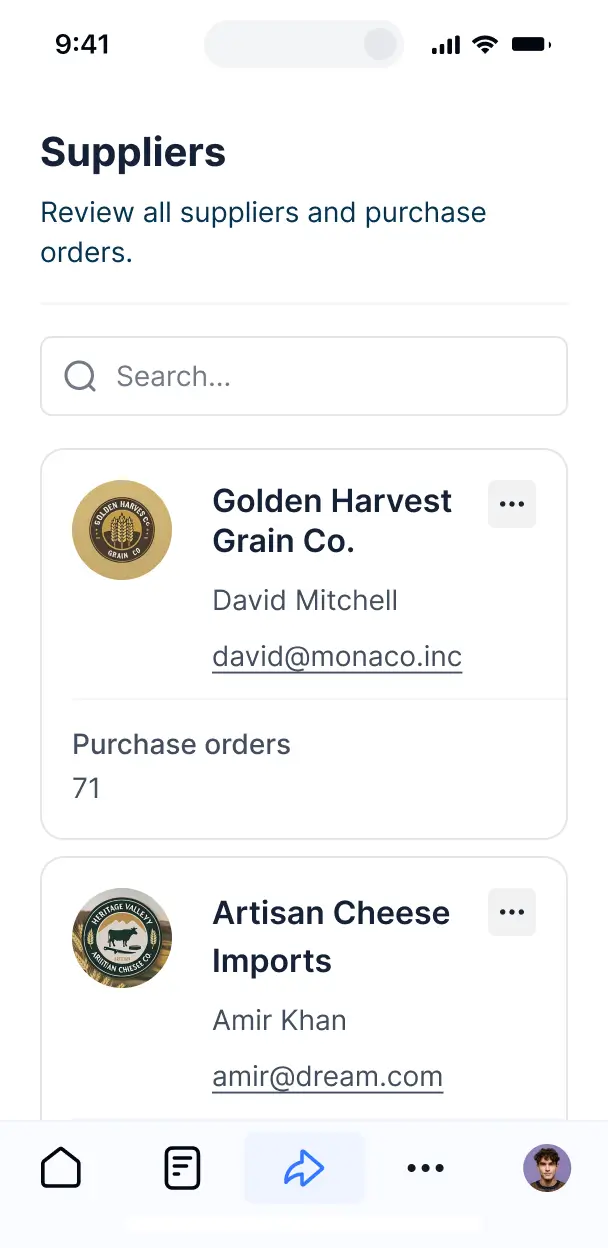

Custom access for every team. Built-in security, no dev time.

Give your production, warehouse, and management teams the right tools and access to track inventory across all stages. Set roles and permissions easily—no IT needed.

Advanced permissions

Give production staff, warehouse teams, and managers tailored dashboards showing only the inventory info they need.

User groups

Give production staff, warehouse teams, and managers tailored dashboards showing only the inventory info they need.

Automations

Connect with tools like Make, Zapier, or N8N to automate inventory updates, reorder alerts, and batch tracking.

Works on any device

Access and update inventory data from the production floor or warehouse. All apps are mobile-friendly by default.

Easy, secure logins

Let your teams log in with Google, email, or SSO—giving secure access to inventory tools with zero IT hassle.

Security

Keep your inventory and operations data secure with SOC2 and GDPR compliance, plus detailed access controls by role.

.svg)

An AI assistant for food ops

Teams can ask AI about stock, orders, or usage and get instant, accurate answers—all within your inventory system.

Why Softr vs other software

No more one-size-fits-all tools or costly custom builds. Softr is easy to use and fully customizable, so you can launch faster, adapt as you grow, and skip the complexity of traditional software.

Easy, fast setup

Set up your food inventory tracking in minutes with drag-and-drop blocks and ready templates.

Consolidate your stack

Add features for batch tracking or supplier data as your inventory processes change—no rebuild needed.

Flexible as you grow

Manage stocks, suppliers, and orders—all in one place, with no extra logins or tools required.

Build a fully custom inventory tracker in minutes

Connect to your data in seconds

Integrate with your spreadsheets and databases, including Airtable, SQL, Hubspot, Google Sheets, Supabase, BigQuery, and more—in just a few clicks. Your data is always secure and in sync.

Customize layout and logic

Drag and drop customizable building blocks with various views and functionalities. Granular permissions allow you to control what data each user can access, and which actions they can take.

Publish and launch

Ship applications that your team will love in minutes or hours, instead of days or weeks. Deploy on both desktop and mobile.

250+

600+

Frequently asked questions

A food manufacturing inventory management software is a centralized, secure platform where your team can track raw materials, monitor finished goods, and manage stock levels throughout the production process. It brings all your inventory data together in one place, so you don’t have to juggle spreadsheets, emails, or manual logs. This makes it much easier to stay organized, spot issues early, and keep production running smoothly.

Softr makes it easy to create a food manufacturing inventory management platform tailored to your specific workflows. You can connect your existing data sources—like Airtable, Notion, SQL, or other databases—and set up a system where your team can log in to view inventory levels, update stock records, and generate reports, all from a single dashboard.

There’s no need for coding. You can start with a template or design your own layout, control who can access which data, and customize the look to match your operation’s branding. It’s quick to deploy, simple to update, and flexible enough to grow with your production needs. In short, it helps your team stay in sync and ensures inventory is always up to date.

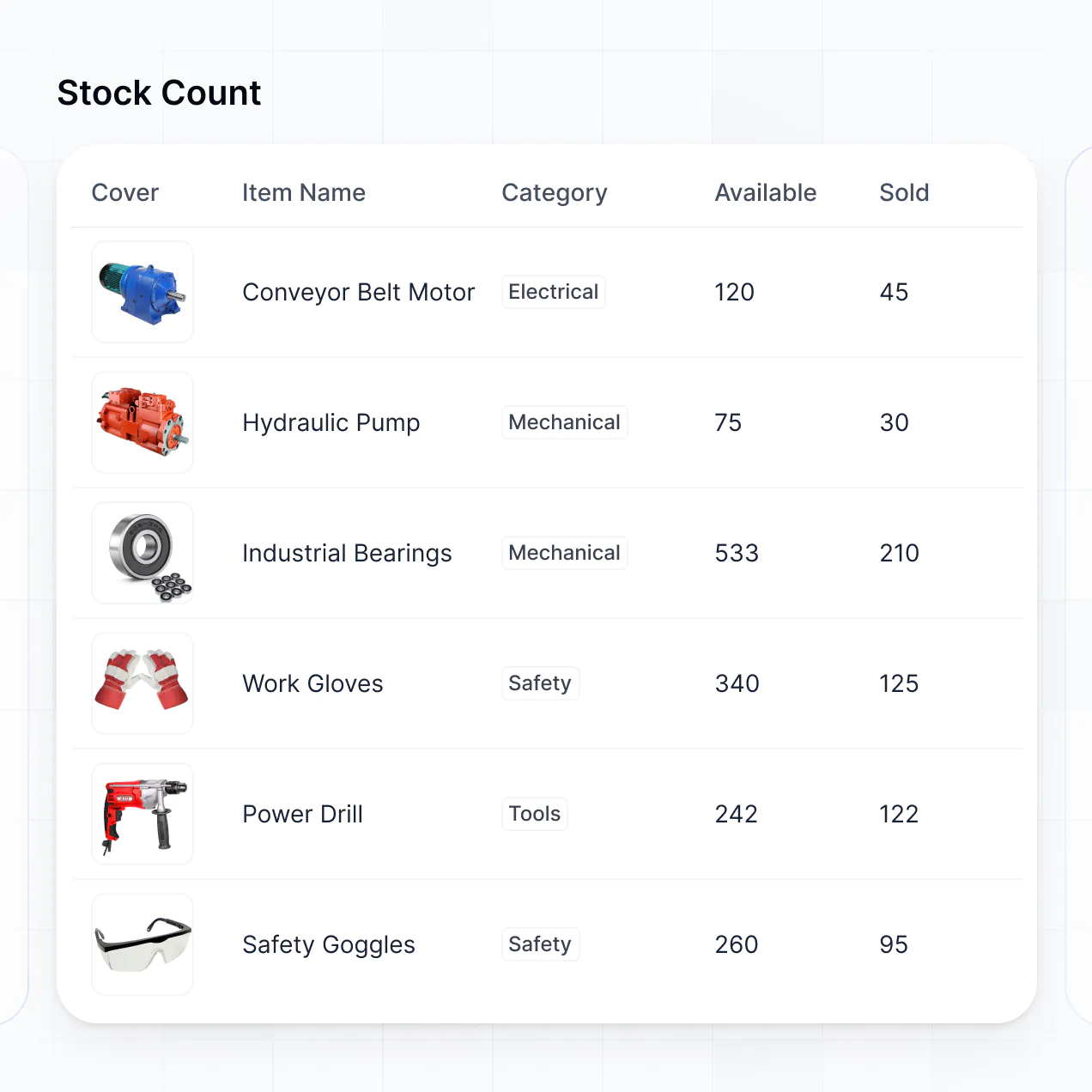

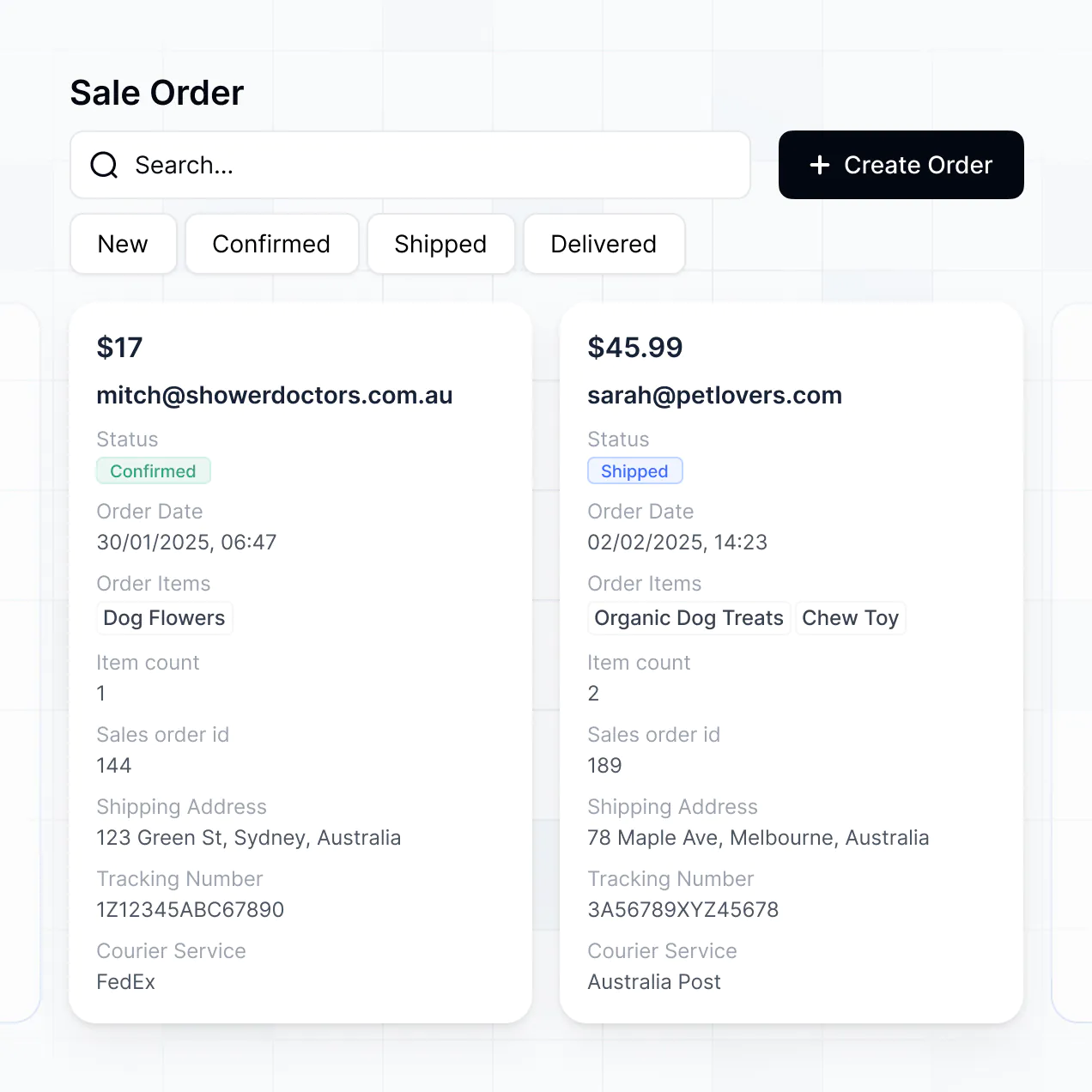

You can build a wide variety of features into your food manufacturing inventory management software, all based on your production and warehouse needs. Some commonly used features include:

\- User logins – so each team member accesses relevant inventory and production data

\- Custom dashboards – to show stock levels, order histories, and production statuses

\- Forms – for receiving raw materials, recording wastage, or logging quality checks

\- File sharing – for uploading compliance documents, batch records, or certificates

\- Search and filters – to quickly find specific inventory items or production lots

\- Tables, lists, and detail views – to display ingredient lists, supplier info, or batch tracking

\- Comments or status updates – to document production notes or flag issues

\- Charts – to visualize usage trends, expiry dates, or inventory turnover

\- Calendar view – for tracking deliveries, audits, or production runs

\- Permissions and roles – so staff, managers, and auditors only see what they need

All of these features are built with Softr’s drag-and-drop tools, making it easy to refine or expand your system as your business needs evolve.

No coding skills are needed. You can build your food manufacturing inventory management software entirely through Softr’s visual interface. Everything from setting up workflows to customizing dashboards and user permissions can be done without writing any code.

Yes. You can manage multiple production facilities or teams within a single inventory management portal. Each user only sees the inventory data and production records relevant to their assigned location or department, based on their login and role. This is especially useful for food manufacturing companies with several sites or teams that need to manage their inventory separately but within a unified system.

Softr supports a wide range of data sources for managing your inventory. You can connect to Airtable, Google Sheets, Notion, Coda, monday.com, HubSpot, Clickup, Xano, Supabase, PostgreSQL, MySQL, SQL Server, MariaDB, BigQuery, and more. You can also bring in data from other sources using the REST API.

You’re not limited to just one. You can integrate multiple data sources into the same inventory management portal and view them side by side—for example, pulling production data from Airtable and inventory orders from Google Sheets. Most sources support real-time, two-way sync, so inventory updates in your portal or data source stay in sync automatically.

Yes, Softr gives you full control over how your team and facility managers experience your food manufacturing inventory portal. You can tailor the layout, navigation, and content to match your company's processes and branding. Each page or block can be shown or hidden based on who’s logged in, so each team only sees their own inventory data.

You can also set up different user roles, such as facility manager, warehouse staff, or admin—and define exactly what each role can view or edit. For example, warehouse staff might only see stock levels, while managers can adjust inventory and view reports. You can also create personalized dashboards by filtering data for each user or department.

This customization ensures your inventory management portal is organized, secure, and tailored to each user’s needs across your food manufacturing operations.

Yes, you can. You don’t need to import your inventory data from another system to start building your food manufacturing inventory management portal with Softr. If you’re starting from scratch, you can use Softr Databases, which are built into the platform and integrate seamlessly with your inventory workflows.

If you already track your inventory in tools like Airtable, Google Sheets, HubSpot, Notion, Coda, monday.com, Supabase, or SQL, you can connect those too. There’s also a REST API connector for bringing in data from other sources. Either way, you have full control over how your inventory data is organized and displayed in your portal.

Yes, you can fully white-label your food manufacturing inventory management software built on Softr. You can use your own logo, brand colors, fonts, and custom domain so your software feels like a true extension of your company. You can also remove all Softr branding, so your team and stakeholders only see your organization’s identity throughout the entire experience.

Absolutely. Softr gives you a lot of flexibility to customize both the design and layout of your food manufacturing inventory management software. You can adjust colors, fonts, spacing, and page structure to reflect your company’s visual style. You can also decide how inventory and production data appears, set up workflows for your team, and determine what different users can see and do when logged in.

To organize your manufacturing and inventory data, you can add different types of blocks, such as:

\- Table blocks – to display inventory lists, ingredient batches, production schedules, or quality checks

\- List or Card blocks – to highlight suppliers, product categories, or equipment details

\- Detail View – to show one product, batch, or record at a time

\- Forms – for logging inventory changes, restocks, or quality issues

\- Charts – for visualizing inventory trends or production efficiency

\- Calendar blocks – to track production runs, shipments, or maintenance dates

If you need to update your content or design later, it’s easy to make changes in the visual builder.

Softr is built with security in mind. All your food manufacturing inventory and production data is encrypted in transit (TLS) and at rest, and your software runs on secure, reliable infrastructure. Softr lets you manage exactly who can access different parts of your inventory system—set up role-based permissions, control user access directly through your connected data source, and use visibility rules to protect sensitive manufacturing information.

If your software is connected to external data sources like Airtable or SQL, Softr doesn’t store your data—it simply displays it in real time according to your access settings. You’re always in control of your data and who can edit or view it.

Softr also follows industry best practices for authentication, access control, and monitoring to keep your inventory and manufacturing information safe.

You can get started for free. Softr’s Free plan lets you publish one app with up to 10 users and 2 user groups, and supports all standard data sources like Softr Databases, Airtable, Google Sheets, and more.

If your inventory management system needs more users or advanced features, you can explore the paid plans to suit your manufacturing operation’s requirements: <https://softr.io/pricing>

Softr is designed to help you quickly create user-friendly, fully functional apps—like food manufacturing inventory management systems—without needing to write code or hire developers. What makes Softr stand out is how easily you can go from concept to working software, and how well it integrates with your existing inventory data.

Unlike some no-code tools that are more focused on mobile apps or are developer-centric, Softr is great for non-technical teams that want full control over layout, user access, and workflows. You can build on top of real-time data from tools like Airtable, Google Sheets, Softr Databases, or SQL, and create secure, branded software your production and warehouse teams can use daily.

You have visual control over everything—from how your inventory is displayed to who can see which sections. Softr includes built-in features like user roles, forms, conditional logic, and API support, so you don’t need to patch together multiple tools to create a powerful inventory management solution.

Yes, Softr supports a wide range of integrations so you can connect your inventory management software to other tools in your manufacturing stack. You can automate tasks using Zapier, Make, or N8N—for example, to trigger restock orders, send notifications about low inventory, or log completed production runs. Softr also supports REST API and webhooks for more advanced workflows.

Whether you need to sync data with ERP systems, trigger automations based on inventory changes, or display information from other manufacturing tools, you can build these processes into your software—no coding required.