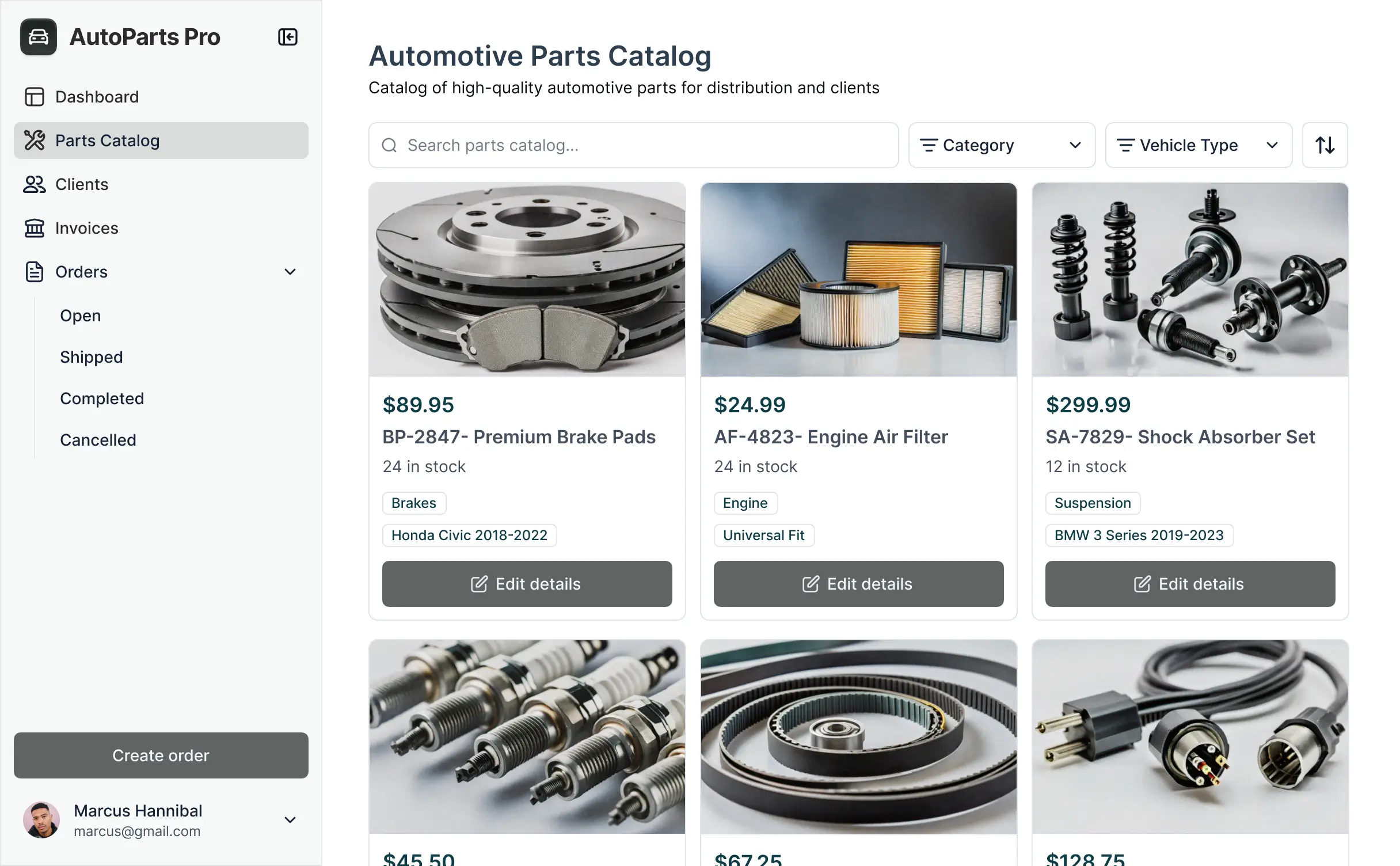

Build manufacturing knowledge base, no code required

Organize and share critical manufacturing insights with a customizable knowledge base tailored to your team's unique processes.

Tailor your knowledge base to your needs

Build a manufacturing knowledge base with only the views and workflows your team needs. Add or adjust features as processes and requirements change.

Centralize your manufacturing data in real time

Connect spreadsheets, ERP systems, and quality control tools with real-time sync—or manage everything in Softr Databases. Create a single source of truth for your operations.

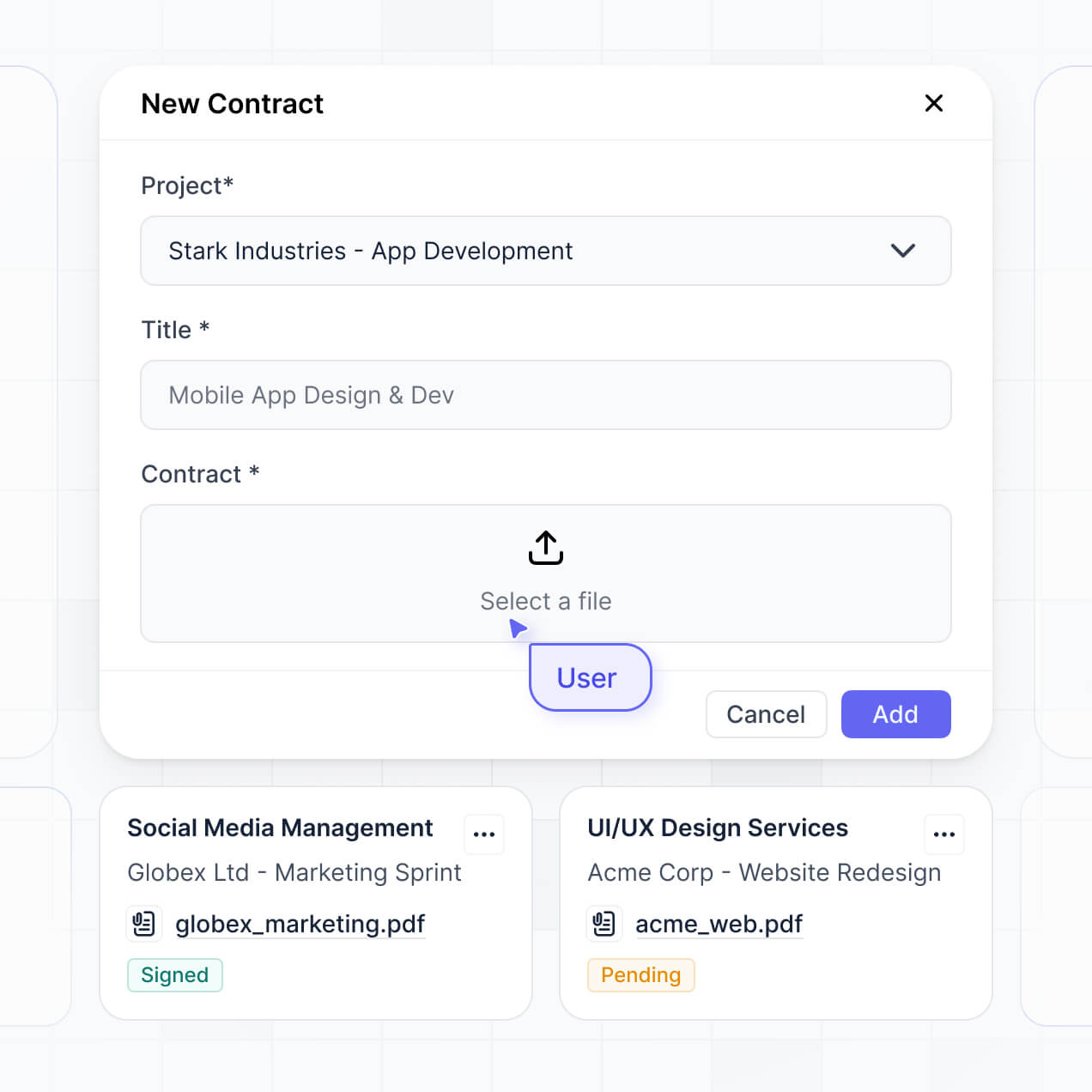

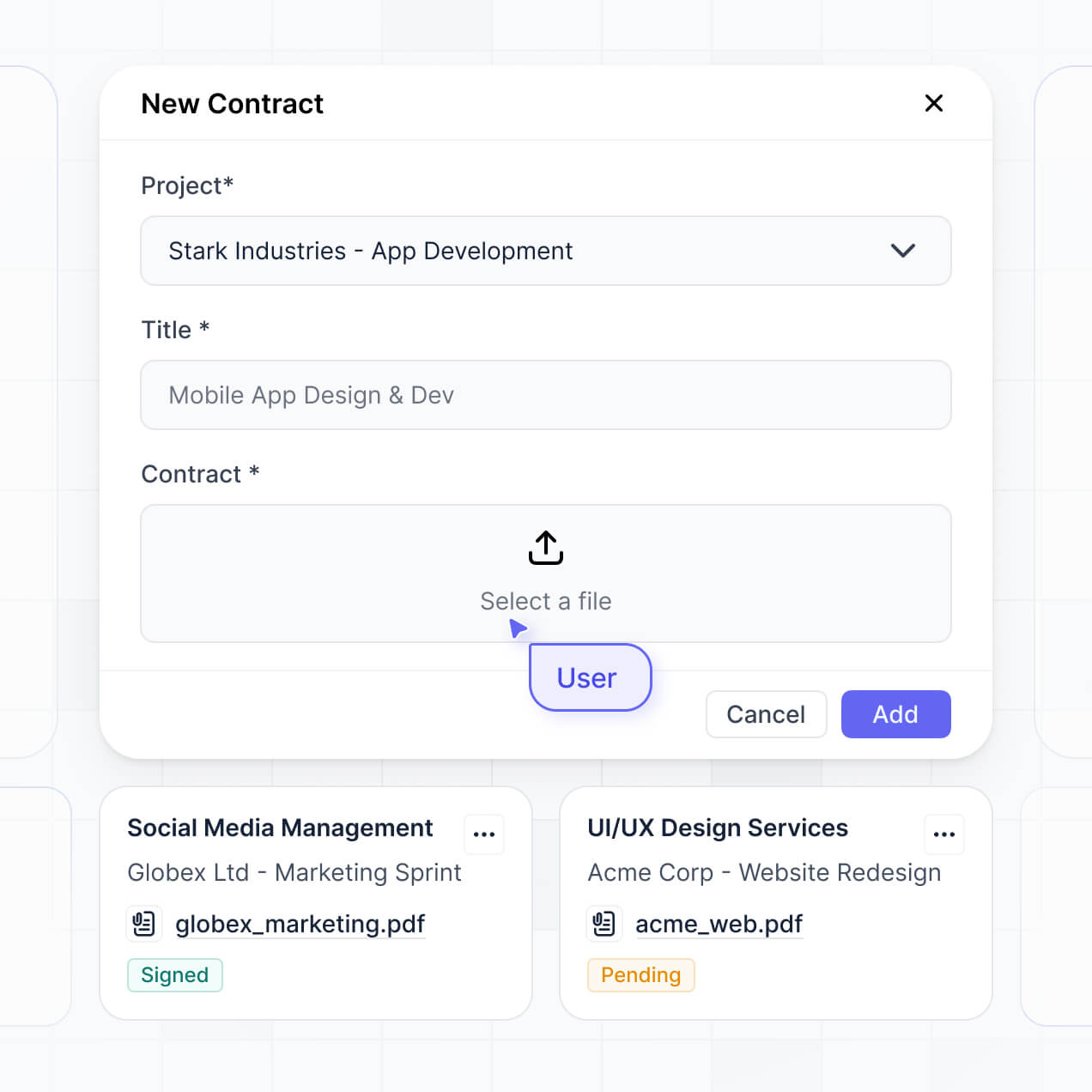

Give every user a custom, secure knowledge base.

Deliver a fully branded manufacturing knowledge base with tailored access for each user. Set up secure logins, roles, and permissions in minutes.

Easy, secure logins

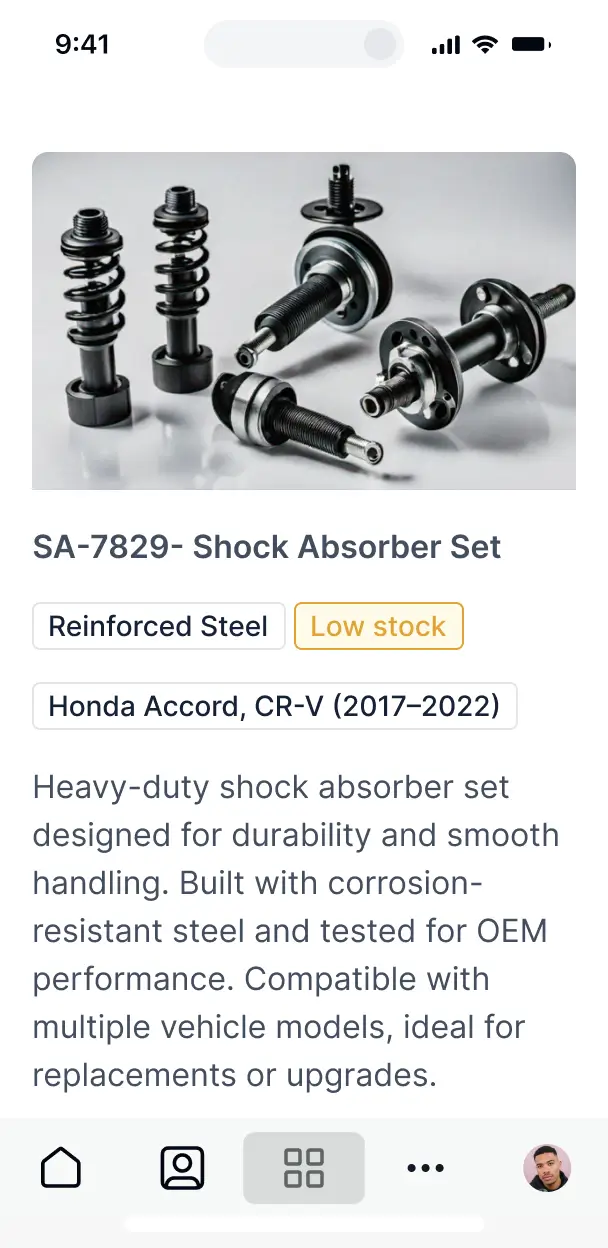

Access your manufacturing knowledge base on desktop or mobile. Always up-to-date, wherever you need it.

Works on any device

Access your manufacturing knowledge base on desktop or mobile. Always up-to-date, wherever you need it.

Automations

Integrate with existing tools to automatically update documents, notify teams of changes, or trigger reviews.

User groups

Set up different user groups—such as engineers, operators, or suppliers—each with custom dashboards.

Advanced permissions

Define who can view, edit, or manage specific knowledge articles, down to the document or section level.

Security

Protect proprietary manufacturing information. Softr meets SOC2 and GDPR standards for robust data security.

.svg)

An AI assistant for manufacturers

Let your team ask AI about processes or products—answers surface instantly inside your knowledge base, powered by Softr.

Why Softr vs other software

No more one-size-fits-all tools or costly custom builds. Softr is easy to use and fully customizable, so you can launch faster, adapt as you grow, and skip the complexity of traditional software.

Easy, fast setup

Launch your manufacturing knowledge base in minutes using drag-and-drop blocks and templates.

Consolidate your stack

Easily add procedures, document updates, or new sections as your operations and teams evolve.

Flexible as you grow

Centralize manuals, SOPs, and training docs—all in one place, with no extra tools needed.

Build a fully custom manufacturing knowledge base in minutes

Connect to your data in seconds

Integrate with your spreadsheets and databases, including Airtable, SQL, Hubspot, Google Sheets, Supabase, BigQuery, and more—in just a few clicks. Your data is always secure and in sync.

Customize layout and logic

Drag and drop customizable building blocks with various views and functionalities. Granular permissions allow you to control what data each user can access, and which actions they can take.

Publish and launch

Ship applications that your team will love in minutes or hours, instead of days or weeks. Deploy on both desktop and mobile.

250+

600+

Frequently asked questions

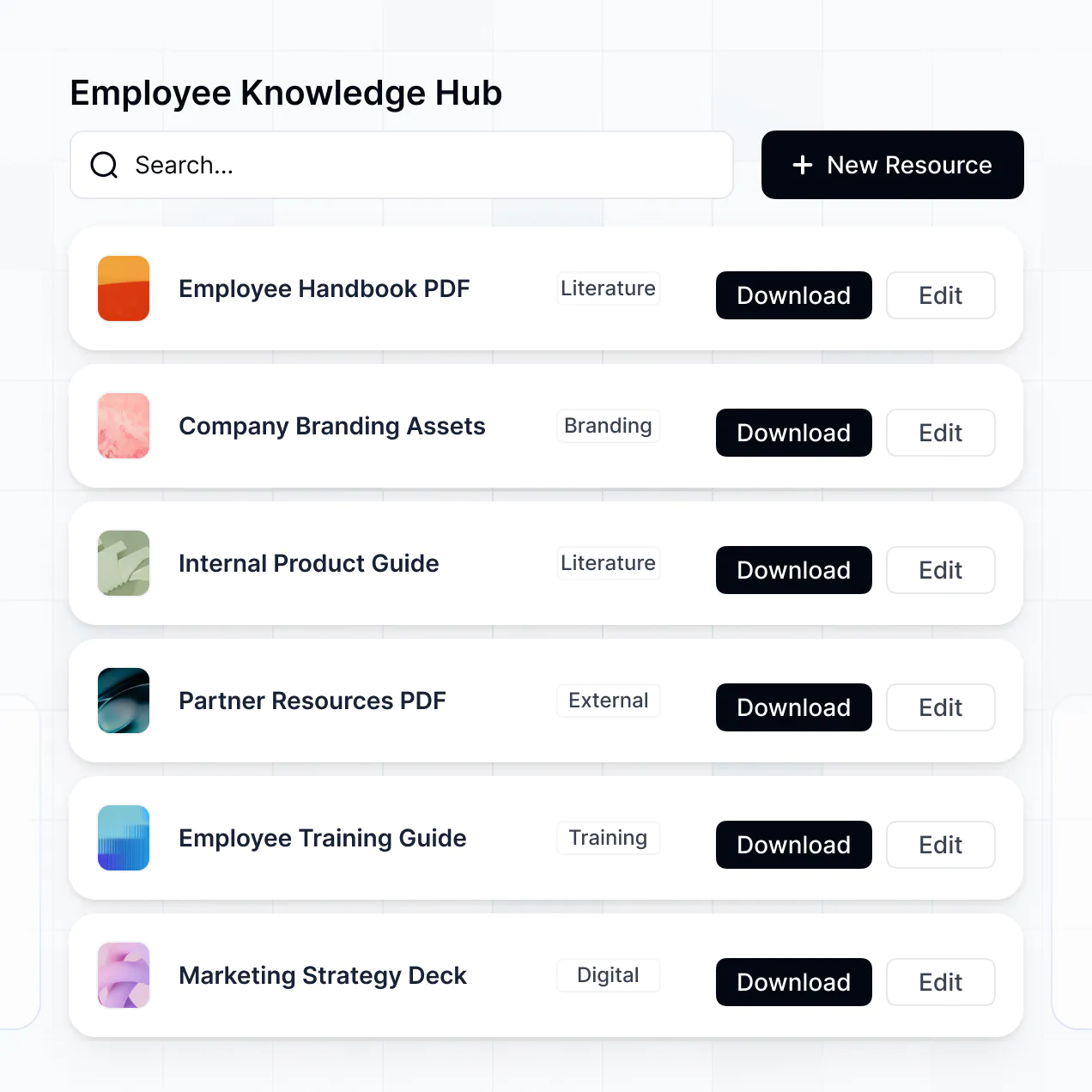

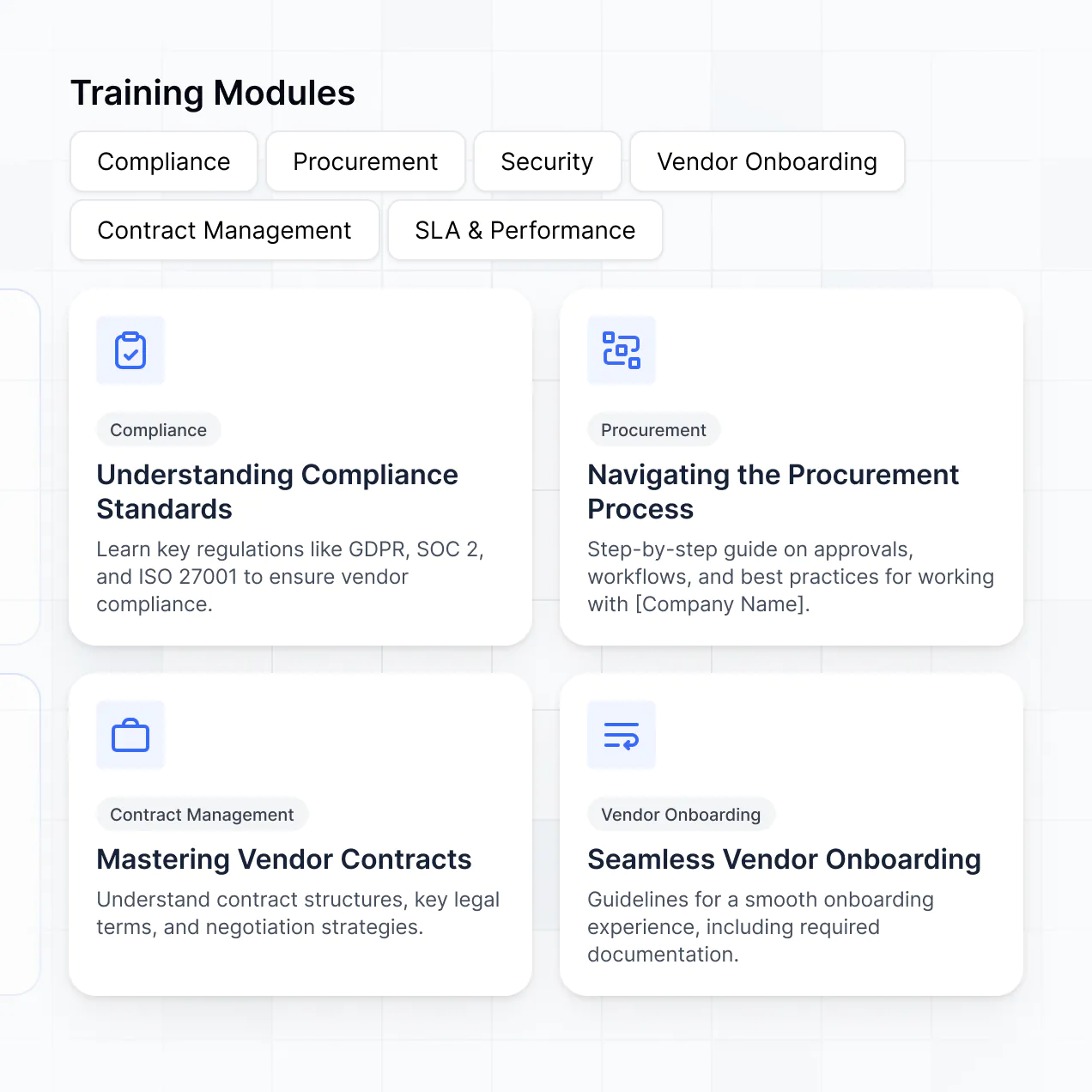

A manufacturing knowledge base is a secure platform where your team can access vital information related to processes, equipment, standard operating procedures, troubleshooting guides, and production updates. It centralizes all key documents and resources so you don’t have to rely on scattered files, emails, or paper manuals. This helps your manufacturing team stay organized, quickly find answers, and keep operations running smoothly.

Softr makes it straightforward to build a manufacturing knowledge base that fits the needs of your shop floor, engineers, and supervisors. You can connect your existing data—from spreadsheets, Airtable, Notion, or SQL—and organize it so employees can easily find procedures, safety information, and training materials, all in one place.

You don’t need any coding experience. Start with a template or build your own structure, adjust layouts, set permissions for different roles, and apply your company branding. It’s quick to set up, easy to keep updated, and flexible enough to scale as your manufacturing processes evolve.

You can include a wide range of features in your manufacturing knowledge base, depending on how your facility operates. Common examples include:

\- User logins – so each operator, technician, or manager can access the right resources

\- Custom dashboards – to display KPIs, process updates, or maintenance schedules

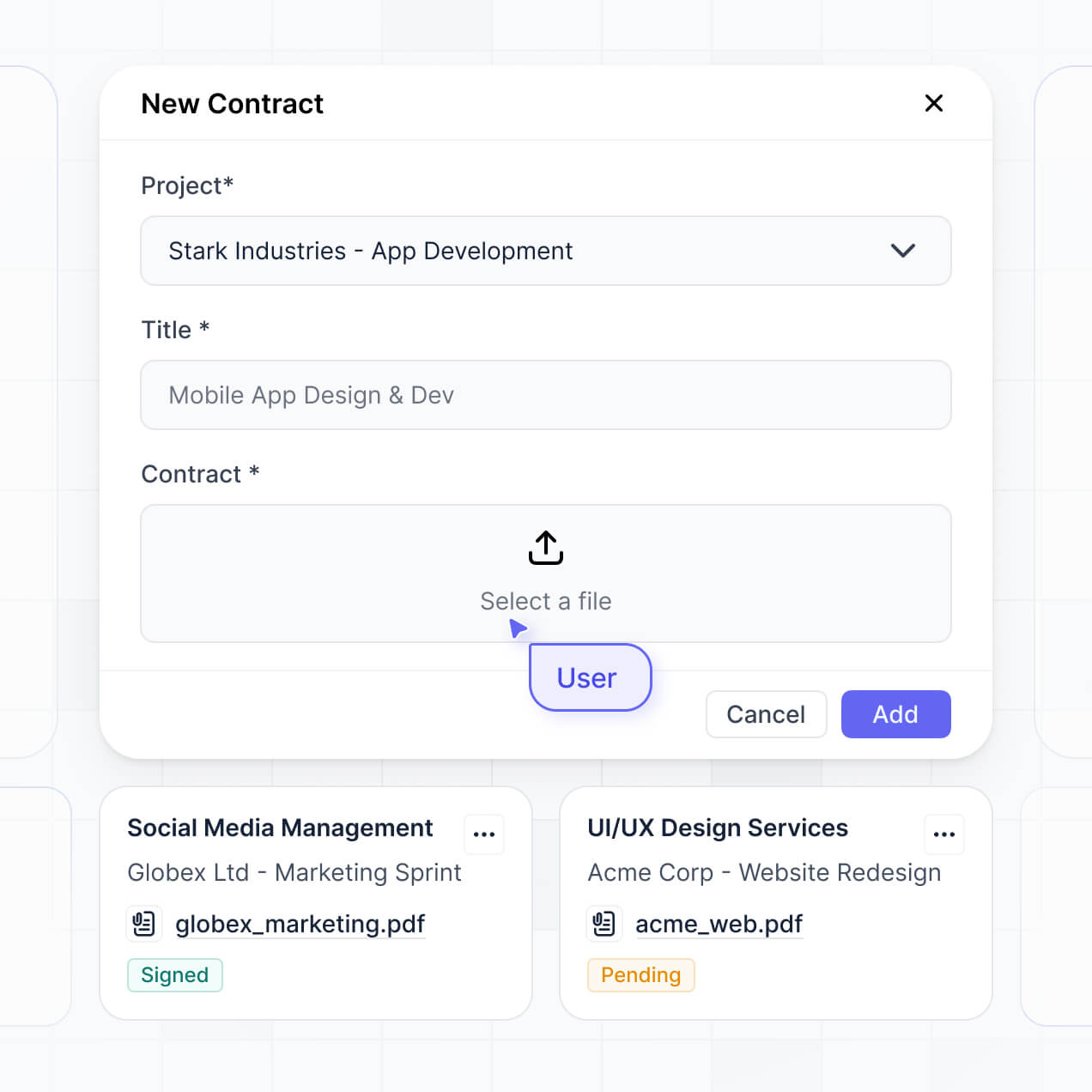

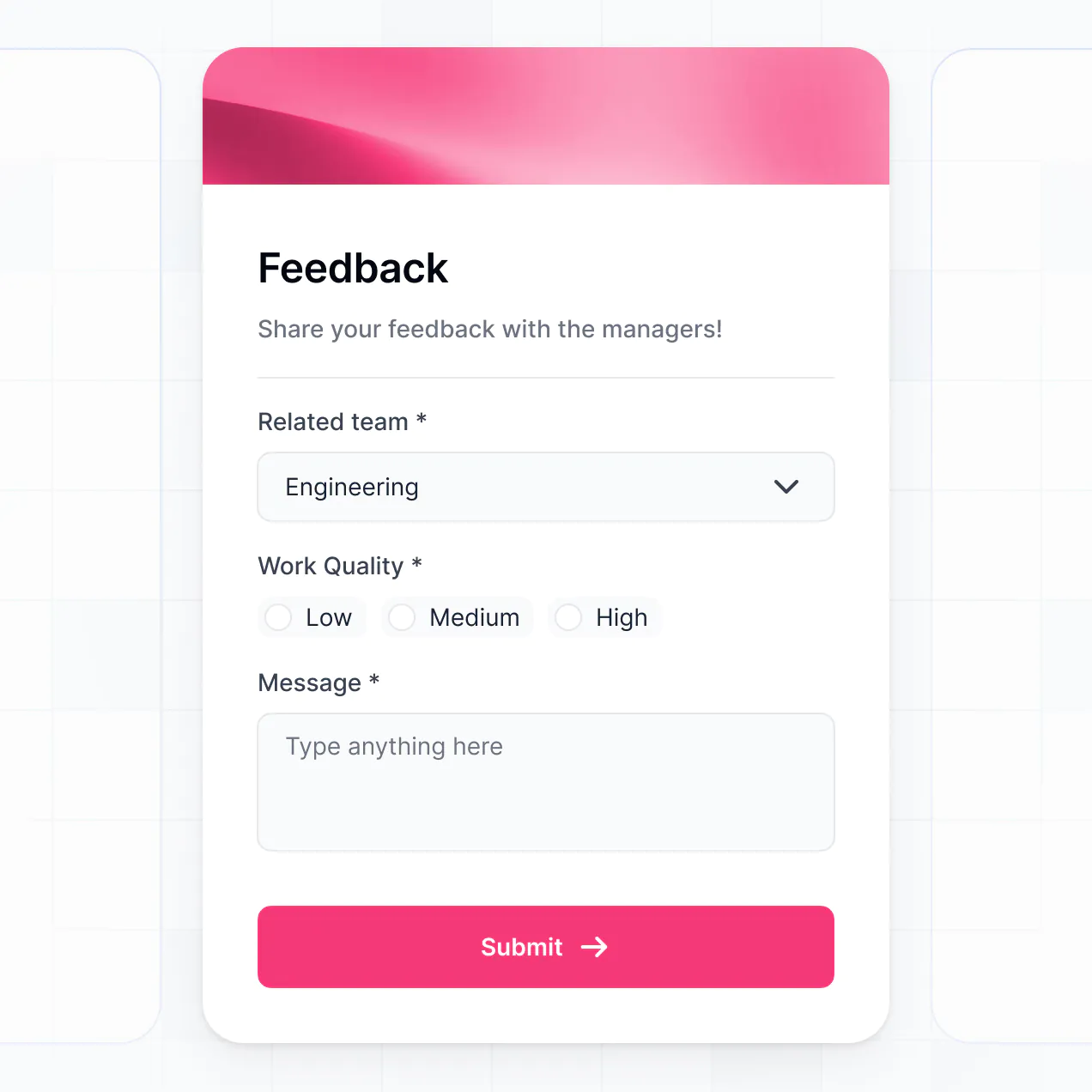

\- Forms – for submitting incident reports, maintenance requests, or feedback

\- File sharing – upload and access SOPs, safety data sheets, and equipment manuals

\- Search and filters – to help users quickly find procedures or troubleshooting steps

\- Tables, lists, and detail views – to organize parts inventories, process flows, or training records

\- Comments or status updates – to keep track of handovers or shift changes

\- Charts – to visualize production metrics, downtime, or quality trends

\- Calendar view – for tracking preventive maintenance, audits, or training sessions

\- Permissions and roles – so only authorized users can see or edit sensitive information

All these features can be created using Softr’s drag-and-drop tools, so you don’t have to write any code. If your operations change, it’s easy to update the knowledge base.

No coding is needed. You can build your manufacturing knowledge base entirely using Softr’s visual editor. Everything from the page layout to user permissions can be customized without writing a single line of code.

Yes. You can manage multiple teams or departments within a single manufacturing knowledge base. Each user will only see the documents, SOPs, and resources assigned to them, based on their login and role. This setup is ideal for manufacturing organizations with different production lines, engineering groups, or quality assurance teams that need access to specific information.

Softr supports a wide range of data sources for your manufacturing knowledge base. You can connect to Airtable, Google Sheets, Notion, Coda, monday.com, HubSpot, Clickup, Xano, Supabase, PostgreSQL, MySQL, SQL Server, MariaDB, BigQuery, and more. Data from other sources can also be brought in using the REST API.

You aren’t limited to just one data source. You can integrate several at once and display them side by side—so your manufacturing knowledge base can pull in information from, for example, both Airtable and Google Sheets. Most sources allow real-time, two-way sync, ensuring that updates in your app or original data source are reflected automatically.

Yes, Softr gives you full control over how users interact with your manufacturing knowledge base. You can tailor the layout, navigation, and content to fit your company’s structure and processes. Pages or sections can be shown or hidden depending on the user’s role—so, for example, operators see only the procedures relevant to their equipment, while engineers and managers can access broader sets of documentation.

You can also define different user roles, such as operator, supervisor, or administrator, and specify exactly what each role is allowed to view or edit. Personalized views can be configured by filtering content based on the logged-in user. This level of control is especially helpful for manufacturing environments where different teams or shifts require access to distinct sets of knowledge, keeping the experience streamlined, secure, and tailored.

Yes, you can. You don’t need to import your manufacturing data from another platform to get started with Softr. If you’re building your knowledge base from the ground up, you can use Softr Databases, which is built into the platform and integrates seamlessly with your knowledge base application.

If you already store manufacturing documents or data in tools like Airtable, Google Sheets, Notion, or other supported platforms, you can easily connect those as well. The REST API connector lets you bring in data from additional sources, so you have full control over how your manufacturing processes and documentation are organized and displayed.

Yes, you can fully white-label your manufacturing knowledge base in Softr. You can use your company’s logo, brand colors, fonts, and custom domain to ensure the knowledge base feels like a natural part of your organization. You can also remove all Softr branding, so your team and partners see only your manufacturing company’s identity throughout the platform.

Yes, you can. Softr gives you a lot of flexibility to control the design and layout of your manufacturing knowledge base. You can adjust colors, fonts, spacing, and page structure to match your company’s branding standards. You can arrange each page, select which content blocks go where, and set what different users—such as production teams or suppliers—see when they log in.

To organize your manufacturing data and documents, you can use different types of blocks depending on your needs:

\- Table blocks – to display structured data like equipment lists, process documentation, or maintenance logs

\- List or Card blocks – to highlight key resources, safety guidelines, or standard operating procedures

\- Detail View – to show specific documents or knowledge articles one at a time

\- Forms – for collecting feedback or reporting issues

\- Charts – to visualize production metrics or quality data

\- Calendar blocks – to track maintenance schedules or training sessions

If your documentation or design requirements change, it’s easy to update your knowledge base in the visual builder.

Softr is built with security in mind. All manufacturing knowledge base data is encrypted in transit (TLS) and at rest, and your apps are hosted on secure, reliable infrastructure. Softr gives you full control over who can access and modify knowledge base content. You can set up role-based permissions, manage users within your data source, set visibility rules, and apply global restrictions to protect sensitive manufacturing information across your knowledge base.

When connecting to external data sources like Airtable, Notion, or SQL, Softr doesn’t store your data—it simply displays it based on your access settings. You’re always in control of your information and who can view or update it.

Softr follows industry best practices for authentication, access control, and platform monitoring to keep your manufacturing knowledge secure.

You can get started for free. Softr’s Free plan lets you publish one app with up to 10 users and 2 user groups, plus support for all standard data sources like Softr Databases, Airtable, Google Sheets, and more.

If your manufacturing knowledge base needs more users or advanced features, you can review the paid plans here: <http://softr.io/pricing>

Softr is designed to make it easy to build fully functional, user-facing apps—like manufacturing knowledge bases and internal resource hubs—without writing code or relying on developers. The main advantage is how quickly you can go from an idea to a working knowledge base, and how easily it connects with your existing manufacturing data.

Unlike some no-code tools that focus on mobile apps (like Glide) or are more developer-oriented (like Retool), Softr is built for non-technical teams who want control over layout, user experience, and permissions. You can build on top of real-time data from Airtable, Google Sheets, Softr Databases, or SQL, and create secure, branded knowledge bases your employees, technicians, or partners can access.

You can visually customize everything—from content and structure to access rules. With built-in user roles, forms, conditional logic, and API support, you don’t need separate tools to launch a professional knowledge base.

Yes. Softr supports a wide range of integrations, so you can connect your manufacturing knowledge base with the rest of your technology stack. You can automate tasks or sync information using Zapier, Make, and N8N, and integrate with tools like Slack for notifications or document management systems for file storage. Softr also supports REST API and webhooks for advanced automation.

Whether you want to trigger alerts when new procedures are published, send data to other systems, or display information from manufacturing software, you can build these workflows into your knowledge base without writing code.